Coating

Arizona Thin Films maintains state of the art vacuum coating equipment capable of producing a wide variety of optical coatings from the Ultraviolet to the Infrared. Below is a listing of some common optical coatings that can be manufactured. In-house design expertise makes custom coating specifications available upon request.

Tailored Optical Coating Solutions

Below is a listing of common optical coatings that can be deposited on most optical glasses, crystalline or metallic substrates.

Antireflection (AR) Coatings

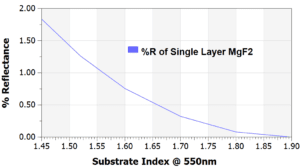

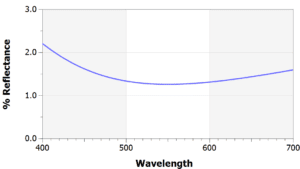

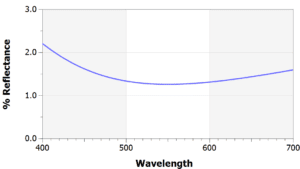

MgF2 – One of the most commonly used antireflection coatings, a quarterwave optical thickness layer of Magnesium Fluoride can act as a highly durable coating when deposited under appropriate conditions. The minimum reflectance achieved depends on the substrate index. This makes MgF2 attractive as an AR coating for imaging systems where the lenses are often of high index, and the incident angles on the lens are high.

Single Wavelength AR Coating (V-coat) – For more narrowband AR performance, such as in laser-based systems, the V-coat is an appropriate choice. The wavelength of minimum reflectance may be chosen for any wavelength in from the ultra-violet to the infrared, and typical performance is <0.1% reflectance at the target wavelength.

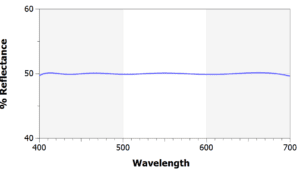

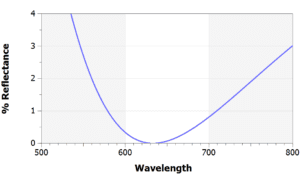

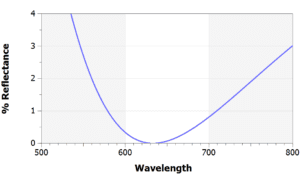

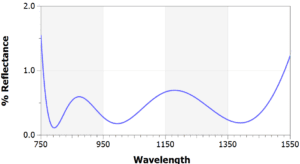

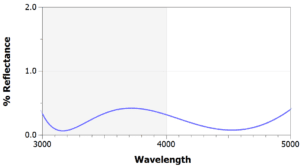

Broadband AR Coatings

Broadband antireflection coatings may be designed to minimize reflectance over a desired wavelength range. In general, the wider the antireflection band, the higher the average reflectance over that band will be. Custom broadband AR coatings are available in the from the visible to the infrared spectrum.

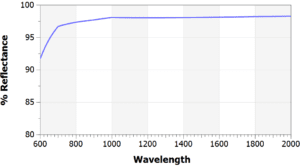

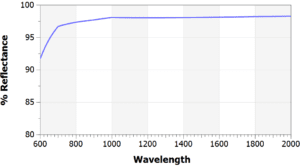

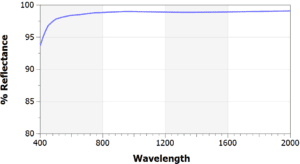

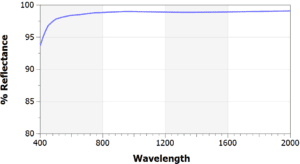

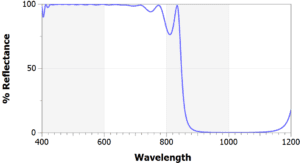

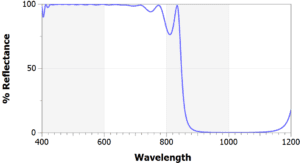

High Reflectors

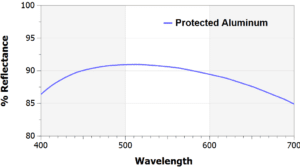

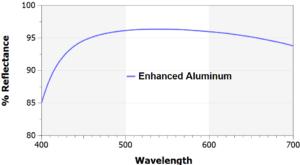

Metallic coatings exhibit high reflectance over broad wavelength ranges. Aluminum is the most common, and may be deposited with a hard and transparent dielectric protective layer to increase durability. Alternatively, multiple dielectric materials may be added to Aluminum to increase its reflectance over a desired wavelength range. Aluminum has high reflectance from the deep UV to the infrared.

Custom specifications for metallic mirrors are available upon request.

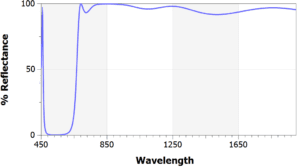

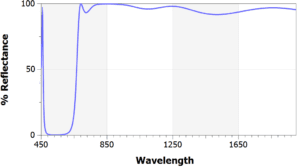

Dielectric High Reflectors – Dielectric high reflectors, sometimes referred to as dichroics, can be designed with custom blocking and transmission ranges to suit a variety of applications. Custom specifications are possible upon request.

Beamsplitter – Beamsplitters can be designed to be used in ambient air, or immersed inside a prism. Custom wavelength ranges from the visible to the infrared and nearly any ratio of reflection to transmission can be designed for. Additionally, filmstacks for meeting polarization requirements can be designed.